Mid-stream operations

Mid-stream operations – An introduction

Like the container terminals, mid-stream operations provide a way of loading and unloading containers on board ships moored at buoys or anchorages in the harbour, but at lower fees. The mid-stream operators served a wide range of vessels, from semi to fully cellular container ships, bulkers and break-bulk carriers.[21]

The lower fees charged by mid-stream operators are attractive to owners of small- and medium-sized ships, who also tend to find this a more efficient option. Unlike a container ship alongside a berth at the container terminals, which can only be loaded on the crane side, mid-stream operations allow the loading and unloading of containers on both sides of the ships while at sea, saving time as well as average cost in handling each container. Even though the service does not apply to large ships, mid-stream operations amount to an important percentage of total throughput starting from the 1980s, especially in the years when the container terminals were close to their maximum capacities. For example, in 1983, the mid-stream industry accounted for 10.9% of the total throughput, and the figure reached 30% in 1992 and 1993.[22]

The mid-stream industry before and after 1972 – The system on bulk cargoes and containers

Before the introduction of containers, ships used in mid-stream operations were constructed mainly from wood. Bulk cargoes were transferred to wooden barges which were then towed to the shore by tugs. The types of bulk cargoes being transported were highly diversified: rice from Southeast Asia, food and frozen foods, bricks and sugar cane from the Mainland.[23]

Mid-stream operations subsequently evolved to fit into the container system; equipment was improved and carrying capacity was increased. According to the Marine Department’s statistics for vessel size distribution in various Public Cargo Working Areas (PCWAs) in November 1993, most of the ships using the facilities were between 20 and 32 metres in length in order to fit the size of the containers. This indicated the prevalent use of containers.

The operating boats – Tugs and barges

Tugs are used to pull or tow larger ships inside the harbour. In a narrow channel like that of Victoria Harbour, tugs are necessary for barges, that had no engines, or for huge ships with minimal steering ability. Like with barges, the tug industry has existed long before container shipping’s rise to popularity. Starting from the 1960s, tugs were used extensively to help meet the needs of Hong Kong’s flourishing export trade. The increasing numbers of large ships entering Hong Kong translated into a strong demand for tugs. By the 1980s, the container freight industry dominated the use of tugs, triggering another evolution in facilities to cope with the increasing size of the barges.[24]

The container freight industry also affected the structure of tugs, which were mainly made of wood before the 1970s. In the mid-1970s, metal tugs with about 365 horsepower were introduced to provide more tugging power to ships weighing around 800 tonnes. By the 1990s, after years of development, the horsepower of tugs reached 1,500, which enabled them to handle ships over 2,850 tons.[25]

Steel barges started to appear in Hong Kong in the 1950s when the shipping industry was rejuvenated following the Second World War. Most of the barges used to transport bulk cargoes were not equipped with engines, making the tugs indispensable in moving them. In the 1970s, barges increased their carrying capacity from 300 to 1,000 tonnes, and raised their lifting ability from 20 to 50 tonnes. Even with the fierce competition from the container terminals, the barge industry prospered in this period, for barges were able to approach directly the container ships berthing at anchorages and buoys, and transfer goods from them to different areas on the shore. This avoided the possible congestion associated with land transport, which together with the reasonable loading speed and the comparative low cost, enabled the barge industry to continue to develop. Thanks to the scrap metal industry that once flourished in Hong Kong, many barges were made of materials reclaimed from old ships; in the 1980s, however, the steel barges came to be specially designed.[26]

Barges also contributed significantly to the development of Hong Kong’s port by carrying cargoes of such natural materials as sand, metals and stones, thereby performing a service not provided by the container freight industry.[27] The concept of using barges in the mid-stream industry was once unique to Hong Kong. Other countries began to adopt the system when they saw how successful it was. For example, some African countries started using barges in developing their own ports.[28]

The operating areas – the mid-stream sites

The mid-stream sites in Hong Kong are mainly used for loading and unloading ocean and river cargoes from barges to trucks or lorries and vice versa. After years of development, mid-stream sites can now be found at various locations, occupying a total land area of over 30 hectares and a water frontage of over 3,500 metres. Both long-term and short-term tenancies are provided to the operating companies.[29]

![Plate 2: Plan for the Port of Hong Kong, 2012.<sup>[30]</sup>](../images/graph/PtICh7_image002.jpg)

Plate 2: Plan for the Port of Hong Kong, 2012.[30]

Public Cargo Working Area

The evolution of Public Cargo Working Areas

Owing to the rapid development of the container industry, the demand for land for handling containers has increased. Barges engaged in mid-stream operations need berthing spaces to load and unload the containers and other cargoes taken to and from ocean-going vessels. In 1971, the Port Committee advised that working conditions at the various public cargo-handling areas were becoming onerous as imports and exports rose. More effective control was needed to achieve better co-ordination on the landward and seaward sides of the seawalls. Before the establishment of Public Cargo Working Areas (PCWAs), cargo operations across the seawall were conducted at the uncontrolled seafront, causing control and traffic problems. PCWAs were then established for handling cargo across the seawall.

In 1974, the Port Control (Cargo Working Areas) Ordinance (Cap. 81) established PCWAs to meet the demand. The first PCWA was established in Wan Chai, and berths were allocated on a first-come-first-served basis. In 1995, the Marine Department managed nine PCWAs and two public waterfronts. By that time, all the PCWAs opened daily from 7 a.m. to 9 p.m., and cargo operations might be permitted upon application.

Hong Kong-Macau Ferry Terminal and China Ferry Terminal

The introduction of dynamically supported craft

In the mid-1960s, the Shun Tak group introduced a hydrofoil, the Coloane, on the Hong Kong–Macao routes, shortening the travelling time to 70 minutes. Since then, various types of dynamically supported high-speed craft have been introduced to Hong Kong for different routes, including those within the Pearl River Delta area. The Hongkong and Yaumati Ferry Company Limited even introduced hovercraft for a local route between Central and Tsuen Wan in 1974.[31] After this, high-speed craft underwent various stages of evolution, from Hydrofoil to Jetfoil, Jetcat, Catamarans, Tricats, etc.

The number of high-speed craft operating between Hong Kong and the Pearl River Delta ports increased rapidly in the 1990s. In 1995, the Marine Department and the Shipping Register of China considered implementing unified safety requirements for high-speed craft operating in the region. As a result, representatives of both administrations met in Guangzhou to start discussions on formulating the unified requirements. On 13 November 1998, a memorandum of understanding on the safety requirements of high speed craft operating between HKSAR and the Pearl River Delta ports was signed between the Marine Department and the Maritime Safety Administration of the People’s Republic of China. Thus began a new era of regional co-operation on the operation and control of high-speed craft.

Hong Kong-Macau Ferry Terminal and China Ferry Terminal

Located at the Shun Tak Centre in Sheung Wan, the Hong Kong-Macau Ferry Terminal is always busy. Facilities at the terminal include a heliport for the Hong Kong-Macao route, ticketing offices, shops and commercial offices. The terminal has an inner pier and an outer pier. The former ensures the efficient berthing of high-speed craft, whilst the latter is reserved for the traditional larger ferries. Due to the huge demand for cross-boundary services, the terminal has been operating around the clock since the early 1990s.

The China Ferry Terminal, previously located at Tai Kok Tsui, was moved to Tsim Sha Tsui in 1988. As a multi-functional terminal, the China Ferry Terminal was also developed with shopping centre, hotel and commercial offices. With the routes within the Pearl River Delta area being mostly operated by Chu Kong Passenger Transport Company Limited, other companies such as the Zhong Shan-Hong Kong Passenger Shipping Co-op Co. Ltd. and the Shun Tak-China Travel Ship Management Limited provide services to other destinations, such as Macao.[32]

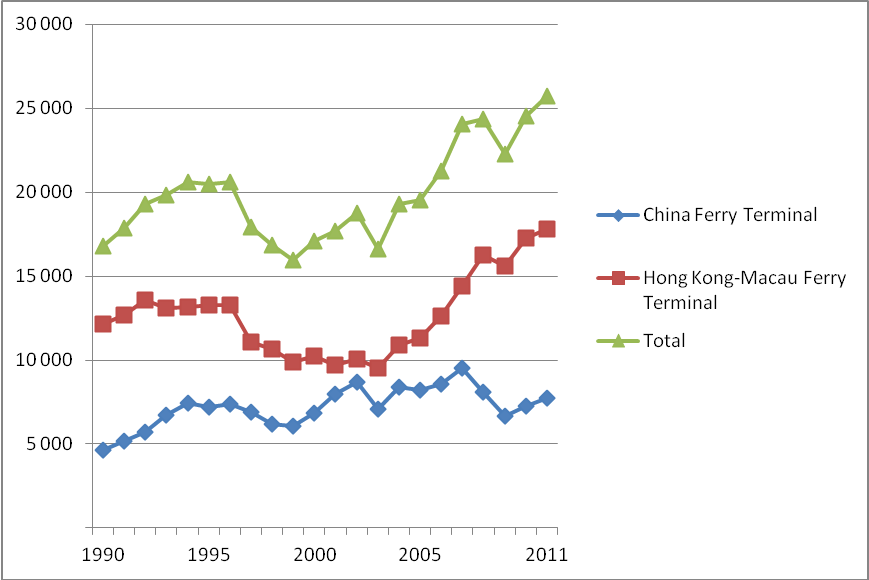

Other than crowd management and ensuring the operational efficiency of the terminals, the Marine Department’s role in the terminals is mainly to regulate the safety of high-speed craft. As the vessels operate day and night, the Marine Department, being the monitoring authority, needs to ensure that the vessels are well-equipped, and that staff are well-trained to operate in every environment. Moreover, the Marine Department is also responsible for the daily operation of the restricted area as well as the management of berths and traffic. From 1990 onwards, there has been a steady increase in the annual passenger throughput, with the total number reaching 26 million in 2013.[33]

Notes:

- [21]The mid-stream Cargo Handling, Port Development Board leaflet, in Leonard K. Cheng and Yue-Chim Richard Wong, Port Facilities and Container Handling Services, (Hong Kong: Better Hong Kong Foundation, 1997), p. 27.

- [22]Ibid., p. 28.

- [23]《同心同渡50載:港九電船拖輪商會五十週年紀念特刊》(香港:港九電船拖輪商會有限公司,2003年),頁132-134。

- [24]Ibid., ,p.127, 131.

- [25]《同心同渡50載:港九電船拖輪商會五十週年紀念特刊》,頁127。

- [26]香港貨船業總商會︰《香港貨船業總商會成立四十七週年暨第二十五屆理監事會就職典禮》(香港︰2010年),頁54。

- [27]Ibid.,

- [28]大公報︰《中流作業模式移植安哥拉》,2009年4月30日。

- [29]Hong Kong Maritime and Port Board, Hong Kong Port – Mid-stream Sites, http://www.hkmpb.gov.hk/en/port/midstream.html, accessed 25/05/2016.

- [30]Map: The Port of Hong Kong.

- [31]《香港與珠江三角洲高速客運渡輪》(香港︰共和媒體,2003年),頁57-61。

- [32]GovHK: Ferry Services to Macau and the Mainland Ports, http://www.gov.hk/en/residents/transport/crossboundary/ferryservices.htm, accessed 16/01/2015.

- [33]《香港與珠江三角洲高速客運渡輪》(香港︰共和媒體,2003年),頁117。